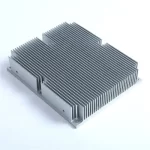

Custom Aluminum Heat Sink Manufacturing

Vertex’s 20 years of heat sink machining experience ensures high efficiency, precision, cost-effectiveness, and fast delivery, meeting all requirements.

- Over 40 Certified Materials

- Custom Finishes

- No Minimum Order

- Fast Turnaround

Save 30% on average!

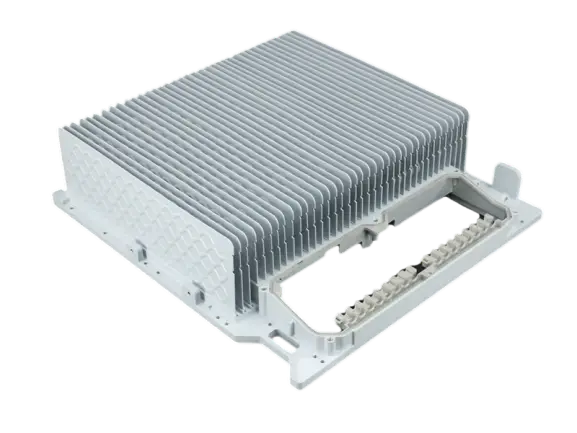

We offers manufacturing services in heat sink by CNC machining services, special custom designs, optimized thermal dissipation performance, and high quality and quality assurance of manufacturing services to attain efficient flow of heat.

Our talented team of engineers and assemblers maximizes accuracy and significantly reduces production time. Control over all processes, from selecting the ideal raw materials and alloys, to world-class fabrication, finishing and assembly, to custom packaging of the finished product, allows us to provide you with cost-effective, high-quality aluminum radiators.

We delivers cost-effective solutions tailored to your volume and process needs, ensuring quality and saving you money.

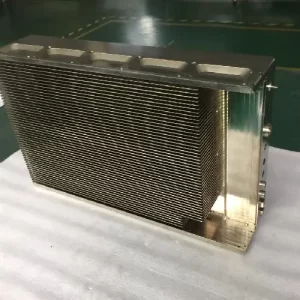

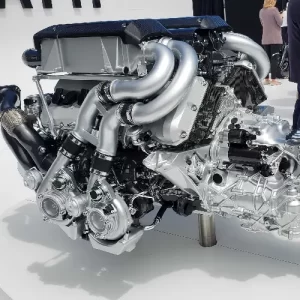

Aluminum is pushed through a die to form long, consistent profiles. Cost-effective, excellent thermal performance, ideal for high-volume production in electronics and automotive industries.

Molten aluminum is injected into molds under high pressure. Suitable for complex shapes, high production rates, good surface finish, and dimensional accuracy, used in automotive and consumer electronics.

Precision machining of aluminum blocks for detailed, customized designs. High precision, flexible design, suitable for low to medium volume production in electronics, medical devices, and aerospace.

- Aluminum Anodizing Surface Finish Services

- Assembly and Packaging Services

- Multiple Grades of Aluminum Alloy Material Options

- Aluminum Heat sink Salt Fog Testing

To test an aluminum heat sink’s thermal efficiency, attach it to a heat source and use thermocouples to measure temperatures at key points. Monitor ambient conditions and record the temperature drop across the heat sink. Analyze the data to determine heat dissipation and thermal resistance, ensuring it effectively cools the device under the specified conditions.

Our company’s quality management system can easily pass the QMS conventions of the aluminum business and has been put into construction and more enhancement annually.

Every product undergoes testing during production throughout the production process as a matter of internal quality control and industry standard as well as extra testing and quality control to meet the customer’s requirement.

You can be sure that you tell me how I can help you, and I shall fulfill your high quality product!

What are the advantages of using aluminum for heat sinks?

Aluminum has excellent thermal conductivity. Aluminum’s thermal conductivity is second only to silver, copper, and gold, and is lightweight, low cost, and easy to manufacture, making it an ideal material for radiators.

What manufacturing processes are used to produce aluminum heat sinks?

Common processes include extrusion, die casting, CNC machining and forging, each offering different advantages depending on the design and application. Extrusion, for example, allows for complex cross-sectional shapes, die casting is the most cost-effective for high-volume production, and CNC machining offers the highest level of accuracy for prototypes and high-precision applications.

How is the thermal performance of an aluminum heat sink measured?

Thermal performance is typically measured by thermal resistance, which indicates how effectively the heat sink dissipates heat from the source.

Can aluminum heat sinks be customized for specific applications?

Yes, aluminum heat sinks can be tailored in size, shape and fin design to meet specific thermal management requirements. Please upload your design and we’ll deliver a good one!

What surface treatments are available for aluminum heat sinks?

Common surface finishing for aluminum heat sinks include anodizing, powder coating, and chromate conversion coatings that enhance corrosion resistance and thermal performance.

How do you ensure the quality of aluminum heat sinks during manufacturing?

Quality is ensured through rigorous testing, including thermal performance tests, dimensional inspections, and material quality checks to meet industry standards.