Your Global Partner for Quality CNC Machining Services in China

Cost-effective CNC machining, prototyping, and production of custom parts. Your project is unique, and we deliver the service it demands.

- Competitive Price 30% cost save

- Fast turnaround in 7 days

- Tolerances down to ±0.005mm

- Global Delivery

- Real Factory welcome visit

Vertex precision tech Ltd provides high-quality prototyping, low and large-volume manufacturing services to support your product development needs. Our international team will work with you to make your product ideas a reality through high-tech CNC equipment and ensure your parts are shipped on time

Our Vision

Our Mission

Our Goal

Our Team

Vertex precision tech Ltd provides high-quality prototyping, low and large-volume manufacturing services to support your product development needs. Our international team will work with you to make your product ideas a reality through high-tech CNC equipment and ensure your parts are shipped on time

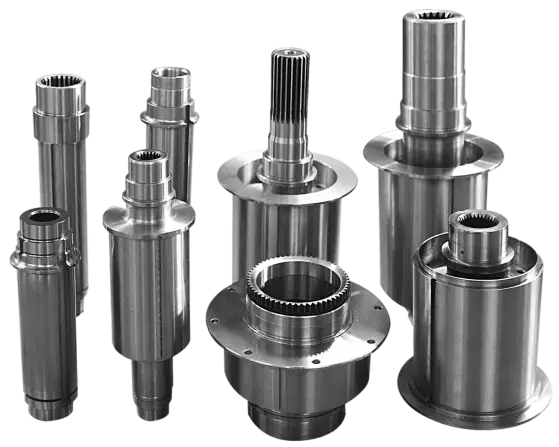

Gear Machining

Finishes Services

Rapid Prototyping

1-50 Quantity by CNC machining, laser cutting, and other techniques.

Low Volume

CNC Machining and Sheet Metal Fabrication are available.

Mass Production

Consistent product quality, CNC machining, casting, and laser cutting are available.

Sub-contract

One-Stop Services Supplier, On-demand manufacturing, Non-Disclosure Agreement available.

Lightweight, corrosion-resistant, highly conductive, versatile in applications.

Dense, malleable, low friction, excellent acoustic properties.

Rust-resistant, strong, hygienic, widely used in industry.

Tough, high tensile strength, foundational in construction.

Exceptionally conductive, malleable, antimicrobial, aesthetically appealing.

Superior strength-to-weight ratio, biocompatible, corrosion-resistant.

Great wear resistance, inexpensive, good for heavy-duty parts

Hard, retains sharpness, abrasion-resistant, ideal for cutting tools.

Resistant to seawater, historic significance, strong, bearings manufacturing

Extremely light, decently strong, flammable as powder or ribbon.

High strength, stiffness; low friction; excellent dimensional stability.

Tough, impact-resistant; easy to machine; popular for prototyping.

Wear-resistant, strong; good sliding properties; absorbs moisture.

High-temperature resistance; superior mechanical properties; chemical resistant.

Extremely low friction; high heat resistance; chemically inert.

Good chemical resistance; easy to weld and machine; durable.

Optically transparent; UV resistant; good weatherability; brittle.

High strength and heat resistance; flame retardant; medical-grade.

Exceptional thermal and chemical stability; high strength and stiffness.

Excellent impact resistance; low moisture absorption; chemical resistant.

The Croma PLUs series three coordinate measuring machine is a precision instrument designed specifically for complex surface detection. It combines precision and speed, setting new standards for accuracy and efficiency. With high precision and efficiency, it can complete various complex measurement tasks and meet the diverse detection needs of various industries.

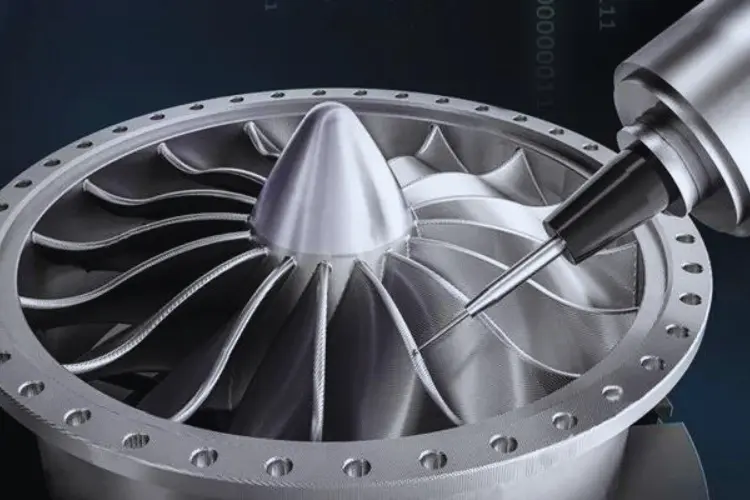

In aerospace, precision is non-negotiable. Our CNC machining services deliver tight-tolerance components from lightweight materials like aluminum and titanium. We manufacture essential parts such as turbine blades, airframes, and landing gear with extreme accuracy and durability.

Meeting stringent industry standards, our expertise ensures components withstand high stress, heat, and fatigue, making them ideal for aviation and space exploration applications.

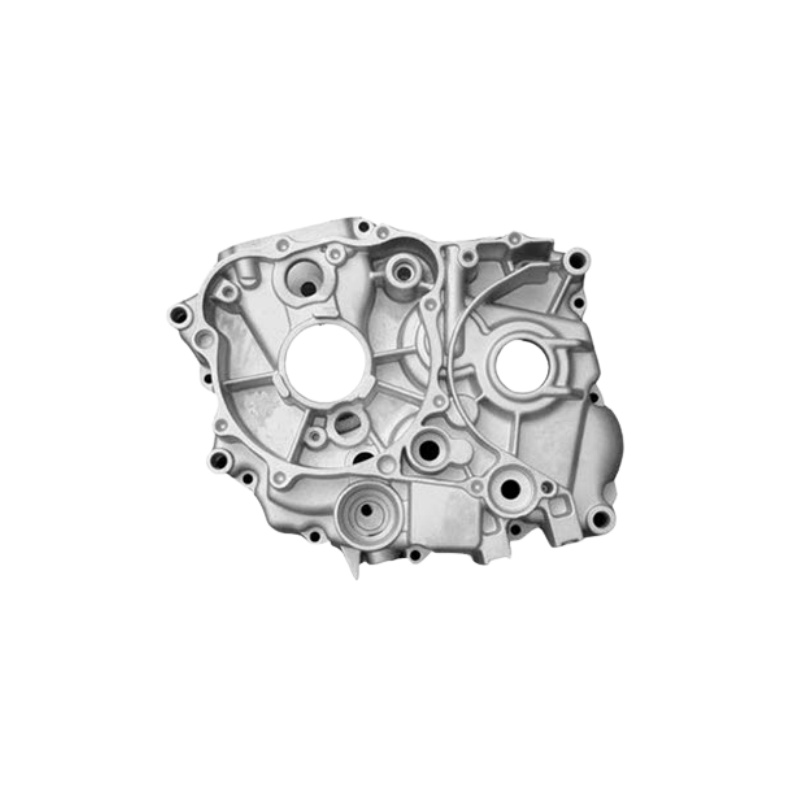

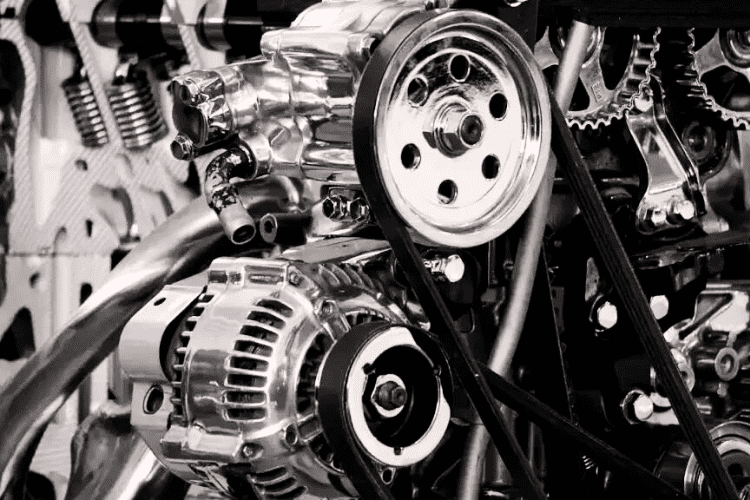

For the automotive industry, we offer scalable production of high-precision components, including engine parts, transmission systems, and braking components.

Utilizing metals like steel and aluminum, we ensure durability, corrosion resistance, and optimal performance under demanding conditions. With rapid prototyping capabilities, we support innovation while maintaining the high quality needed for production parts.

Meeting stringent industry standards, our expertise ensures components withstand high stress, heat, and fatigue, making them ideal for aviation and space exploration applications.

In the medical industry, precision and biocompatibility are essential. We machine surgical tools, implants, and diagnostic equipment from materials like titanium and PEEK.

Our CNC services meet stringent medical standards, delivering high-quality parts with smooth finishes, tight tolerances, and fast turnaround times, ensuring reliability in life-saving applications.

The telecom industry is characterized by rapid technological advancements and evolving standards. Every telecom project may have unique requirements in terms of component design and functionality. Our machining services enable the customization of parts to meet specific project needs.

Vertex’s 20 years of heat sink machining experience ensures high efficiency, precision, cost-effectiveness, and fast delivery, meeting all requirements.

We brings a wealth of experience from crafting thousands of custom shafts, ensuring your project benefits from high efficiency, precision, cost-effectiveness, and swift delivery.

Drawing from our expertise, we'll scrutinize your part's manufacturability, advising on materials and design optimizations to provide cost-reduction strategies tailored to your needs.

VERTEX PRECISION MACHINING commitment to meticulous accuracy delivers parts that consistently meet the strictest specifications, ensuring your projects are executed flawlessly.

Experience significant savings of 30-50% with us, our optimized production processes and stringent cost management, ensuring economical pricing without quality compromise .

Our ISO 9001:2015 certified company guarantees quality through SGS, RoHS certifications, material authenticity, and detailed inspection reports for our customer's peace of mind.

We're dedicated to ensuring a smooth experience, offering personalized service and support from initial consultation to delivery and beyond.We provide 24-hour online service

Time-sensitive projects excel here, as we offer swift production turnarounds without compromising the integrity or quality of our CNC machined parts.We accept expedited projects

“Vertex was able to deliver an accurate and quick service for high quality CNC parts. They offered a range of fabrication options and materials to choose from, to suit our specific budget, lead-time and material requirements. Can’t recommend enough.!!.”

Production Manager

“I cannot express to you how happy I am to do business with you, the parts are flawless! The quality is exactly how I hoped it would be! Please give the highest regards to the CNC programmer(s) that handled the parts! And I also thank you for the excellent packaging!.”

Engineer

“We inspected the parts, everything was within tolerance in terms of dimensions, and the surface finish on the machined faces is really good. Vertex has always given us exactly what we needed .”

President

What is 5-Axis CNC Machining? The Complete Guide to Complex Part Manufacturing

(Meta Description: Unlock

A Comprehensive Guide to CNC Machining PEEK Material: Benefits, Applications, and Tips

IntroductionIn the world

High-Quality Acrylic CNC Machining Services: Achieve High-Gloss Transparency and Precision

Introduction to Acrylic C

What is CNC machining, and why should I choose a CNC machining service in China?

CNC machining is a precision manufacturing process where computers control machine tools. Choosing a CNC machining service in China offers cost-effective, high-quality production with access to advanced technology and skilled labor. Chinese companies are known for quick turnaround times and scalable solutions, making them ideal for global clients.

How do I ensure the quality of parts when working with a CNC machining company in China?

Reputable CNC machining companies in China, like Vertex, follow strict quality control protocols, including ISO certification and advanced inspection methods like CMM. Communication and transparency are key, and we provide detailed reports, samples, and regular updates to ensure your specifications are met.

How much does CNC machining cost per hour in China?

The cost of CNC machining in China typically ranges from $10 to $30 per hour, depending on factors like the complexity of the part, material type, machine type (3-axis, 5-axis), and the expertise of the manufacturer. Prices may vary for specialized services or high-precision projects, but overall, China offers highly competitive rates compared to other regions.

Which country is the best for machining?

China is considered one of the best countries for CNC machining due to its combination of cost-efficiency, advanced technology, and skilled labor. Other strong contenders include Germany and the United States, which are known for high precision and innovation. However, China stands out for offering both quality and scalability at competitive prices, making it an attractive option for global manufacturing projects.

What types of materials can you machine in your CNC machining factory in China?

We offer CNC machining services for a wide range of materials, including metals like aluminum, stainless steel, titanium, and brass, as well as plastics such as ABS, nylon, and POM. Our factory in China is equipped to handle both standard and custom material requirements for various industries.

What industries does your CNC machining company in China serve?

We serve a broad range of industries, including aerospace, automotive, medical devices, electronics, consumer products, and more. Our expertise in precision machining and our ability to work with complex materials make us a reliable partner for any industry worldwide.

How long does it take to complete a CNC machining project in China?

Lead times vary based on the complexity and volume of the order. However, our CNC machining factory in China offers rapid prototyping and fast production, with delivery typically within 3-7 days for standard projects. We focus on efficiency to meet your deadlines without compromising quality.

How can I get a quote for CNC machining services from a Chinese manufacturer?

To get a quote, simply provide us with your part designs, material requirements, and specifications. Our team will review your details and offer a transparent, competitive quote within 24 hours. We serve clients worldwide and offer fast, reliable shipping.