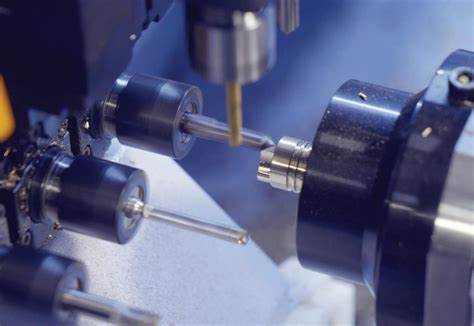

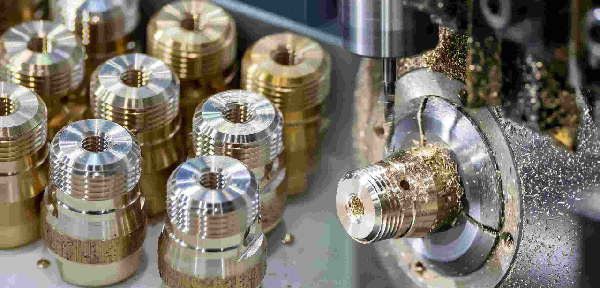

Swiss CNC Machining Services

With 15 years of Swiss CNC machining experience.Vertex can deliver your custom swiss parts to build your brand and grow your profits.

- Machining Diameter from 0.5 to 42mm

- Factory Price

- Tolerances up to ±0.0005"

- Fast Turnaround

Save 30% on average!

Vertex offers high-precision CNC Swiss Machining services to customers in various industries, including aerospace, consumer products, automotive, medical, electronic, sports, and other industrial clients.

From prototyping to full production runs. Our wide range of Swiss CNC machines and CNC lathes and turning centers will allow you to produce high-precision, high-quality parts to meet even your most stringent requirements.

What Is Swiss Machining

Swiss Machining is a manufacturing technique of computer-controlled swiss lathes that are used to produce small, precise parts. The name “Swiss” comes from the fact that these machines were originally developed in Switzerland. Unlike a traditional CNC lathe, which has a single cutting tool, a Swiss CNC lathe has a multi-axis turret that allows for the use of multiple cutting tools. This makes Swiss CNC machines ideal for machining complex parts with tight tolerances. In addition, Swiss CNC machines can run at high speeds, making them ideal for high-volume production. Swiss CNC machines are an essential part of any modern manufacturing operation.

What Is The Benefit Of Swiss Machining

Swiss Machining is a process that has many benefits. It is precise, efficient, and versatile. These benefits make it an ideal choice for manufacturing high-quality parts.

Extremely Tight Tolerances

you benefit from the impressive precision of Swiss CNC machining, which ensures that their parts fit and function as intended. This high level of accuracy reduces the risk of assembly issues or product failure, which can lead to costly redesigns or recalls.

Higher-quality surface finishes

Swiss CNC machines can achieve excellent surface finishes, which is crucial for customers in industries requiring high-quality aesthetics or parts with minimal friction. These superior finishes can improve product performance and appearance, making them more competitive in the market.

More Complex Parts

Swiss CNC machining enables customers to create intricate designs and complex geometries, unlocking innovative product possibilities. This allows for the development of advanced and competitive products, without being limited by manufacturing constraints.

Fast production times

You will experience shorter lead times with Swiss CNC machining, thanks to its efficient design and reduced setup times. This enables them to bring products to market faster and respond quickly to market demands or change your needs.

Consistent quality

Swiss CNC machining is known for its consistency and repeatability, which means You can expect high-quality parts with minimal variation. This is particularly important for industries with stringent quality control requirements, such as aerospace, medical, and automotive.

Reduced material waste

With Swiss CNC machining, You benefit from lower material costs and more sustainable manufacturing practices due to the process's minimal waste. This not only saves money but also supports environmentally responsible production.

Scalability

Swiss CNC machining offers scalability for both low-volume prototyping and high-volume production runs. This flexibility allows customers to develop and test designs without committing to high production volumes, reducing risks and costs associated with product development.

Integrated finishing processes

Many Swiss CNC machines can perform additional operations, such as drilling, tapping, and milling, in a single setup. This integration reduces the need for additional manufacturing processes, resulting in lower costs and shorter lead times for customers.

Transform Your Ideas into High-Quality Components with Our Swiss CNC Machining Services

Comparison Between Swiss-Type Turning And Conventional CNC Turning

Analyzing Key Differences: Swiss-type Turning vs. Conventional CNC Turning

| Comparison Aspect | Swiss-type Turning | Conventional CNC Turning |

|---|---|---|

| Precision & Accuracy | High precision & tight tol. | Good precision & tol. |

| Complexity | Ideal for complex parts | Better for simpler parts |

| Material Waste | Minimal waste | Potential for more waste |

| Setup Time | Faster setup times | Longer setup times |

| Tooling | Multiple tools simultaneously | Single-tool operation |

| Workpiece Size | Limited to smaller diameters | Larger diameters possible |

| Part Holding | Guide bushing support | Chuck holding |

| Secondary Ops. | Integrated operations | Additional setups/machines |

Materials We Work With Swiss CNC Machining

No matter whether plastic or metal, You Can Choose Freely For Your Unique Request.

Swiss Machining Metal

We offers a wide variety of materials for precision swiss machining, metal including but not limited to:

- Aluminum

- Brass

- Stainless Steel

- Steel

- Copper

- Titanium

- Cast Iron

- Tool Steel

- Bronze

Swiss Machining Plastic

We offers a wide variety of materials for custom swiss machining, plastic including but not limited to:

- POM

- Nylon

- PTFE (Teflon)

- Steel

- PEEK

- ABS

- Polycarbonate

- PVC

- Ultem

- PMMA (Acrylic)

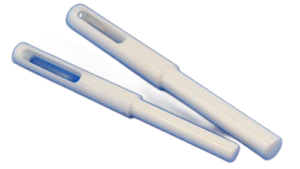

Swiss CNC Machining Application

Exploring Diverse Industries and Use Cases for Swiss CNC Machining

| Part Name | Application | Industry | Material | Finishing | |

|---|---|---|---|---|---|

| Bone Screw | Orthopedic fixation | Medical | Titanium | Passivation |

| Fuel Injector Nozzle | Precision fuel delivery | Automotive | Brass | Electroless Nickel Plating |

| Dental Implant | Tooth replacement | Medical | Titanium Alloy | Surface Texturing |

| Aerospace Fastener | Structural assembly | Aerospace | Inconel Alloy | Anodizing |

| Optical Fiber Ferrule | Optical fiber alignment | Telecommunications | Zirconia Ceramic | Polishing |

| Precision Spindle | High-speed rotation in machinery | Industrial | Stainless Steel | Hard Chrome Plating |

We machine rapid prototypes and low & large volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more.

Swiss CNC Machining FAQ

What materials can be machined with Swiss CNC machines?

Swiss CNC machines can work with a wide range of materials, such as metals (stainless steel, aluminum, brass, titanium, and alloys), plastics, and even ceramics.

How do Swiss CNC machines achieve their high precision and tight tolerances?

Swiss CNC machines utilize a guide bushing that supports the workpiece close to the cutting tool, reducing deflection and vibration. This, combined with the sliding headstock design, enables extremely accurate and consistent machining.

What are the limitations of Swiss CNC machining?

Swiss CNC machining is generally limited to smaller-diameter workpieces (up to ~42 mm), and may not be the best choice for very large or simple parts. Additionally, the initial investment in Swiss CNC machines can be higher compared to conventional CNC machines.

Can Swiss CNC machines create internal threads?

Yes, Swiss CNC machines can create internal threads using specialized cutting tools like taps or thread mills, ensuring precise and accurate thread profiles.

How do Swiss CNC machines reduce setup times?

Swiss CNC machines often have multiple tooling stations and can perform simultaneous machining operations, which reduces the need for tool changes and multiple setups, resulting in shorter setup times.