Recently, CNC machining has become more versatile in the manufacturing space. It is agreeable that there are not many products we use today that do not involve CNC machining. This usage rages from industry to industry while the products all go through a CNC machining process at a particular point of production. Consequently, wide varieties of manufacturers across all industries choose the advantages of CNC services for their manufacturing and fabrication applications. To enlighten you, we have rounded up quality information on the benefits and applications of CNC machining. Read on to learn more.

Advantages Of Using CNC Machining

When it comes to manufacturing complex parts or any other simple parts, CNC machine tools available in CNC shops are beneficial. As a result of the benefits such as high levels of accuracy, speed, and precision. Interestingly, CNC machining digital autonomy and template nearly eliminate human error. Hence, there are wide varieties of advantages, they include

#1 – Quality

CNC machining is dynamic in its mode of action. The CNC machine shops are built to provide the highest form of accuracy for few productions and larger productions. Part created using CNC machining offers high-quality materials and operation, which give CNC machining part resistance to wear and tear. Consequently, you can run a CNC machine using advanced software that can be updated per specification regularly. There will be easy production of super-complex CNC machining parts in this regard.

#2 – Versatility

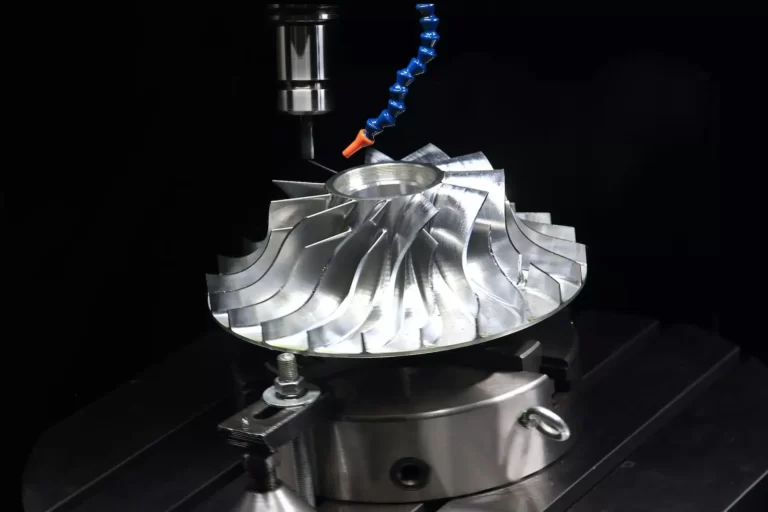

CNC machines are versatile in their mode of action when production is ongoing in CNC machining shops. This versatility is evident in their ability to manufacture CNC machining parts that are very difficult or impossible to manufacture using the traditional methods due to their complex nature.

#3 – Efficiency

In manufacturing, uniformity in production, as well as output match, is essential. Most skilled engineers will manufacture or create a varying product using the conventional method. Unlike this, the incredible efficiency of CNC machining services confers precision in creating an exact component in multiple folds. In addition, CNC machining features more incredible speed in production once you program it using a particular design. As a result, scalability becomes easier.

#4 – Savings

In real-life scenarios, every piece of tool or equipment in conventional machining requires a dedicated technician with skills, experience, and extensive knowledge of the machine. In comparison, CNC machining is highly controlled using a software program in CNC shops. This technique requires less human interaction apart from the data and initial setup. Besides, CNC services require less advanced training, which further reduces the cost of labor. While computers play a significant role in CNC manufacturing, the chances of human error and compromised safety in the workplace are reduced.

#5 – Adaptability

With CNC manufacturing, delivering top-notch accuracy, speed, and precision for a high level of part quantities becomes easy. This fact is true for both high and low orders, so no amount is too small. With its adaptability, CNC machining is applicable in a wide variety of industries across the world.

#6 – Compatibility

Compatibility is probably the most significant advantage it has over conventional machining. Machines for CNC are compatible with almost every type of material, such as metals, plastic, wood, and foam.

Industries That Use CNC Machining

The use of CNC machining services can help improve almost if not all aspects of manufacturing processes. CNC machining is applicable in a wide variety of industries that derive specified benefits from its implementation. They include:

Aerospace Industry

CNC manufacturing is the perfect choice in aerospace. This choice is a result of the need for high repeatability and accuracy in the aerospace industry. The CNC manufacturing features remarkable properties such as tolerances within the order of ±0.0002” to ensure the compliance and safety of extreme critical aeronautical CNC machining parts.

Automotive Industry

CNC machining service is applicable in this space for either prototyping and manufacturing of CNC machining parts. It is useful for the production of one-off custom automotive parts and replacement parts. Since CNC manufacturing offers faster turnaround and no minimum quantity of production, it is highly applicable. Extruded metals can be machined into the following CNC machining parts;

- Valves

- Gearboxes

- Gas gauges

- Dashboard panels

- Cylinder blocks

- Axels

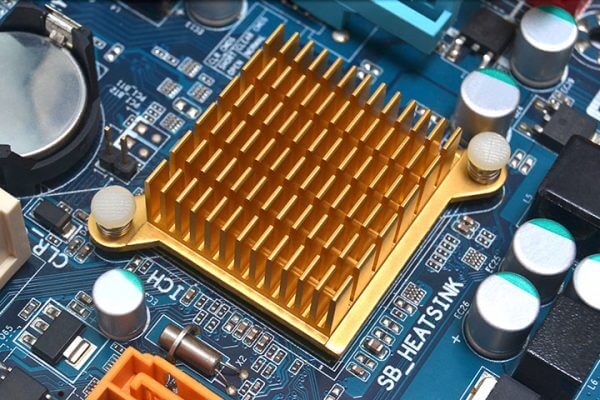

Consumer Electronics

Recently, the trend in consumer electronics is miniaturization. As a result, components become smaller while they retain their compact, lightweight, and power. CNC manufacturing makes it possible to handle specialized materials holding very tight tolerances for the minor components, even throughout the maximum production. With the high process reliability, via integrated CAD solutions, you can put parts rapidly into production after completing the prototyping and testing process. Examples include;

- Semiconductor Support

- PCBs

- Jigs

- Fixtures

- Electronic Industry Support

Housings

CNC machining is highly applicable in manufacturing CNC machining parts for the architectural industry. This applicability is because the accuracy of the design is of greater importance. In this industry, minute details are observed for the safety and longevity of architectural buildings. It can be achieved using the help of CNC machining capabilities.

Defense Industry

CNC manufacturing has a wide range of applications in the defense industry. Examples include prototyping and production of reliable and rugged parts. As a result of CNC manufacturing, these parts withstand wear and tear even with low maintenance. Besides, components that are upgraded are helpful in this industry as it demands constant innovations like security. Applications include:

- Satellite Systems

- Internal Computer Assembly

- Box Cases

Healthcare Sector

CNC machined parts are helpful in various health sector safe materials and one-off custom parts. These parts offer tight tolerances, which are essential for the high performance of such medical components. CNC machining parts are applicable in the following:

- Surgical instruments

- Rapid Diagnostic Test Security

- Orthotics

- Implants

- Electronic closures

Oil & Gas Industry

Tight tolerance is an essential requirement in the oil and gas industry for safety-critical applications. Here, CNC machining is used to achieve reliable, precise, corrosion-resistant materials and many more. Parts have application in refinery and pipeline equipment. Others are

- Valve Bodies

- Rapid Diagnostic Test Security

- Pins

- Fasteners

- Cylinders

Manufacturing Possibilities Of CNC Machining

CNC machining supersedes the conventional control process. Hence, the wide variety of attention it has in the manufacturing industry today. Aside from the application mentioned in the previous section, CNC machining can be categorized by manufacturing possibilities. These possibilities/uses include and are not limited to the following:

Rapid Prototyping

Rapid prototyping is helpful for manufacturers to develop and evaluate prototypes easily, quickly, and economically in their respective CNC machine shops. Hence, CNC machining is ideal for making high-quality rapid prototypes from metals and plastics. Besides, it also helps to avoid the investment in expensive tooling. With this combo, parts can achieve tighter tolerance featuring better surface finishes compared to another prototyping process.

Production

CNC machining makes it possible for manufacturers to produce top-notch CNC machining parts for their target consumers. As a result of the versatility it offers, they manufacture a wide variety of products with durable features. With CNC machining, no quantity is too small for production, and no amount is too much. Hence, CNC machining parts production with this method is limitless.

Tooling

CNC machining offers a world of possibilities to aid processes like injection molding. It provides the ability to machine a wide variety of materials, including steel and robust aluminum. In addition, machined parts like metal mold can be filled using materials to create other products in large quantities.

Hybrid Manufacturing

As the name implies, hybrid is the combination of processes. In this space, the goal of all manufacturers is to produce top-notch parts. As a result, combining the CNC machining process with other techniques such as metal casting or injection molding can help enhance the quality of parts and products.

Final Word

Manufacturers can utilize top-notch accuracy, speed, and precision with CNC machining in the picture for high and low production quantities. Vertex precision machining limited offers world-leading expertise and experience in CNC machining, metal finishing, EDM, rapid prototyping, and many more for a wide variety of industries. We are here to offer you a CNC solution to your manufacturing goals using processes that outperform conventional approaches.

Contact us today to Request an instant Quote.