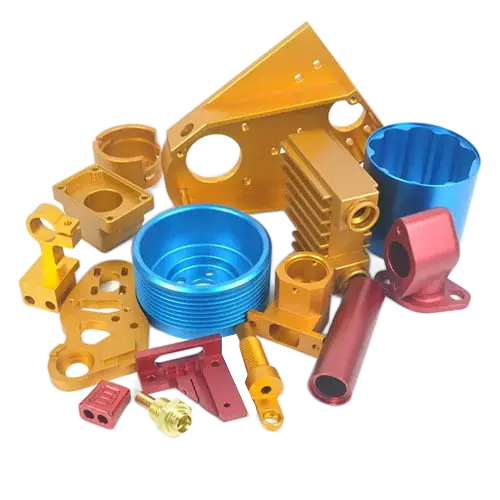

Surface Finishing Services from China

Your one-stop machine shop for manufacturing and surface finishing. Get your metal and plastic parts CNC machined with high quality and aesthetic surface finish. Bead blasting, anodizing, powder coated, etc., in as fast as 7 days.

- Competitive Price

- Global Delivery

- Fast turnaround

- Tolerances down to ±0.005mm

Save 30% on average!

What is Surface Finishing

Surface finishing is the process of altering a material’s surface to improve its appearance, durability, and/or functionality. These techniques can provide an array of benefits, such as corrosion resistance, improved appearance, and better adhesion of paint or other coatings.Here are some of its advantages.

- Corrosion resistance: Surface finishing can help protect materials against corrosion by creating a barrier to prevent contact with corrosive substances.

- Improved appearance: Surface finishing techniques can give materials a polished, smooth, or decorative finish, enhancing their overall look.

- Durability: Surface finishing can improve the durability of materials by making them more resistant to wear and tear, scratching, and chemical damage.

- Better adhesion: Surface finishing can improve the adhesion of paints or other coatings, ensuring they adhere better and last longer.

- Increased conductivity: Surface finishing can increase the electrical or thermal conductivity of materials, making them more suitable for certain applications.

Our Services of Surface Finishing

Our Services of Surface Finishing provide comprehensive solutions. We deliver exceptional results with state-of-the-art technology and a skilled team, ensuring superior quality and customer satisfaction.

Anodizing

Anodizing is a surface finishing technique that creates a protective oxide layer on metals, enhancing corrosion resistance and providing a range of color options for aesthetic purposes, making the material more durable and visually appealing.

Bead Blasting

Bead blasting is a surface finishing process that involves propelling fine abrasive particles at high speeds to remove contaminants, smooth surfaces, and create a uniform texture for optimal adhesion of coatings.

Powder Coating

Powder coating is a popular surface finishing method that involves applying a dry powder to a substrate, creating a durable and attractive finish with excellent resistance to chipping, scratching, and fading.

Electroplating

Electroplating is a versatile surface finishing technique that involves depositing a layer of metal onto a substrate, providing enhanced corrosion resistance and aesthetic appeal.

Finishing Options for Sheet Metal Fabrication

Choose from a variety of finishing options for your sheet metal fabrication project, including powder coating, anodizing, and Electroplating.

|

Name

|

Description

|

Materials

|

Color

|

Texture

|

|---|---|---|---|---|

|

Anodizing

|

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

|

Aluminum

|

Clear, black, grey, red, blue, gold.

|

Smooth, matte finish.

|

|

Bead Blasting

|

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

|

ABS, Aluminum, Brass, Stainless Steel, Steel

|

n/a

|

Matte

|

|

Powder Coating

|

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

|

Aluminum, Stainless Steel, Steel

|

Black, any RAL code or Pantone number

|

Gloss or semi-gloss

|

|

Electroplating

|

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

|

Aluminum, steel, stainless steel

|

n/a

|

Smooth, glossy finish

|

What are some joint surface finishing methods?

Common surface finishing methods include polishing, plating, painting, powder coating, anodizing, bead blasting, and electroplating.

What is the purpose of surface finishing?

Surface finishing serves several purposes, such as enhancing aesthetics, providing corrosion resistance, improving wear resistance, increasing hardness, and facilitating better adhesion of coatings.

How does electroplating work?

Electroplating is a process where a metal coating is deposited onto a substrate by using an electrolytic cell. The substrate acts as the cathode, and a metal anode is immersed in an electrolyte solution. Electric current is applied, causing metal ions to migrate and deposit onto the substrate.

What are the advantages of powder coating?

Powder coating offers advantages like excellent durability, resistance to chipping and fading, an environmentally friendly process (no solvents), a wide range of color options, and the ability to create thick coatings without running or sagging.

Is anodizing only applicable to specific metals?

Anodizing is commonly used for aluminum and its alloys. It forms a protective oxide layer on the surface of the metal. However, anodizing can also be applied to other metals such as titanium, magnesium, and zinc.

What factors should be considered when choosing a surface finishing method?

Factors like the desired appearance, required durability, environmental factors, substrate material, cost, and specific application requirements should be considered when selecting a surface finishing method.

Can surface finishing be applied to different shapes and sizes of objects?

Yes, surface finishing techniques can be applied to objects of various shapes and sizes, ranging from small components to large structures, with proper equipment and expertise.